Collaboration in 2020

Collaboration is a key ingredient to secure opportunities. And a lack of Collaboration is a big impediment. So I was very pleased to see Manufacturers’ Monthly covering a recent project we did that needed Collaboration from multiple industry partners to work.

I presented this case at the IoT Impact 2019 manufacturing stream. I’ll include the main slides for that below. And this is for a product that was Made In Australia, not just because we want to, but because it was the only way it could happen in time.

Collaboration Case Study

The Collaboration Case Study is for the IND Technology Early Fault Detection system that was deployed to a rural SWER Line Monitoring trial as part of the Victorian bush fire amelioration program. This required us to coordinate the program and also do the primary electronics and embedded software design along with our supply partners gearing up for PCB Assembly, Cable and Loom Assembly and mechanical design and production for boxes, mounting and solar panels. All this in parallel with web services. For a new technology category. So we needed to work together very closely.

Collaboration Partners

It takes a team of partners to pull off a project like this. So here are some of the people we collaborated with:

- Precision Electronics Technologies – PCB Assembly

- Connect Electronics – Looms and Wiring Harnesses

- Maries Production Services – metal work, assembly, shipping

And of course IND Technology were highly Collaborative as well.

IoT Impact Slides

These are the slides from the presentation.

A common IoT problem

•Buyers want a catalogue for solutions

•Catalogues don’t contain a viable solution

•There are plenty of sensors available

•Hardware platforms don’t fit the opportunity

•Software back ends are also often a barrier

•Total cost of ownership ends up too high

A possible solution

•Rapid design of a suitable hardware solution

•Get it made locally (in Australia)

•But the catch is that unless very confident, you don’t invest in this until you get the order

•So how quickly can it be done?

Example IND.T

•IND Technology EVFD – finds power system faults – reduces outages and bush fires

•Got the order for 65 trial units end of July 2017

•For Delivery in November 2017 (< 16 weeks)

•For a product not yet designed

•With features not yet confirmed eg. turned out most units had to be solar powered

IND Technology EVFD solar powered

Above is an example of one of the solar powered units as built but without the cover plate over the FPGA based processing systems that samples at 250MSPS.

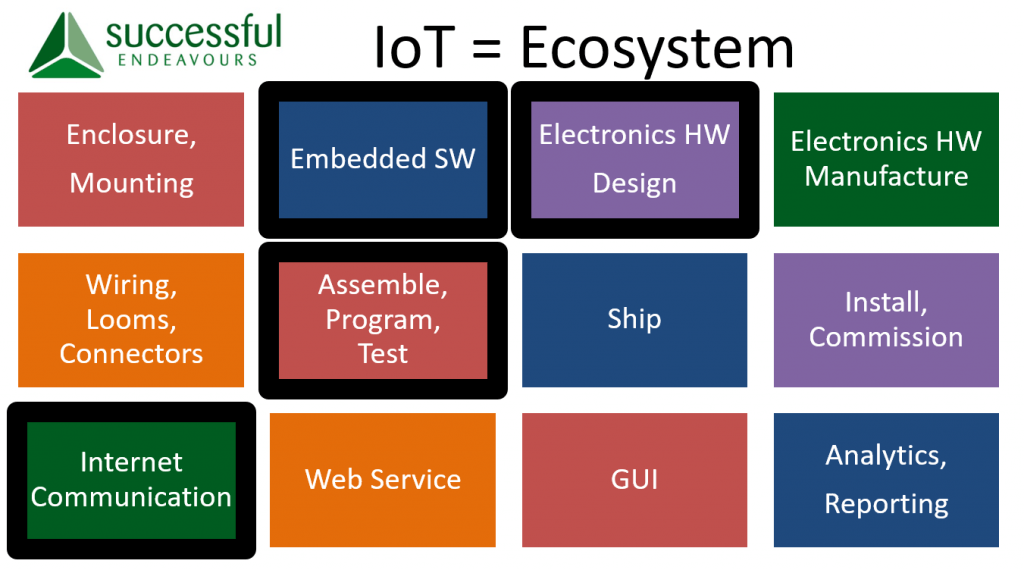

Collaboration Ecosystem

Below is the Collaboration Ecosystem where Collaboration was needed.

The areas with dark borders are the parts we handled internally as well as overall coordination and integration. Each of the other areas was handled by one of our supply partners.

Precision Electronics Technologies received a supplier award for their contribution.

As did Connect Electronics.

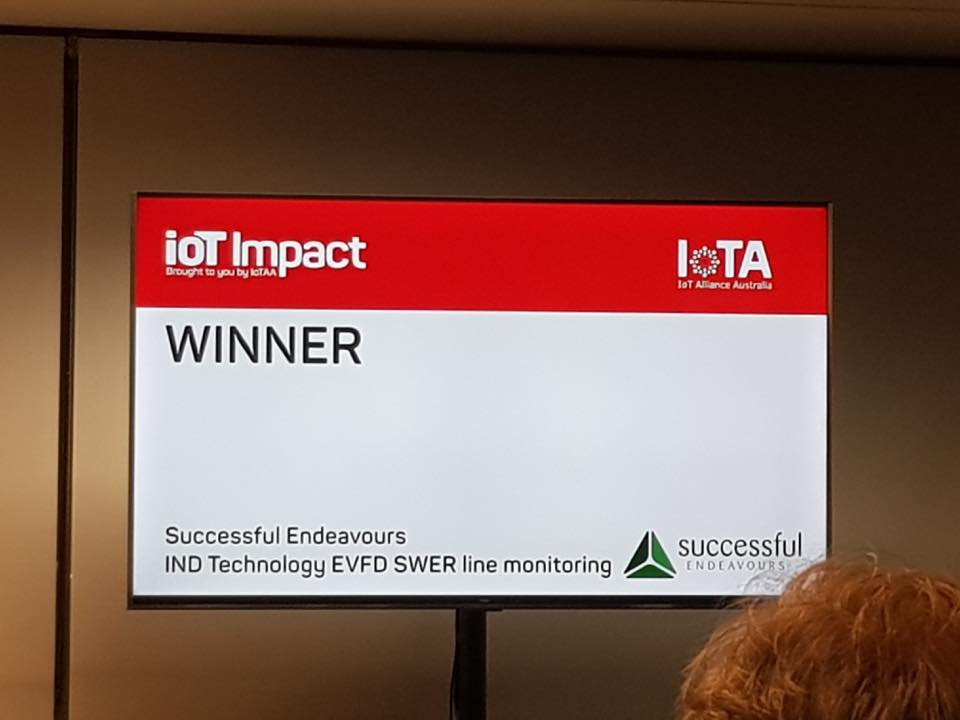

And the overall result won the IoT Innovation Award for 2018.

So a very good outcome all round. And the trial was a resounding success showing that we have another weapon in our arsenal of bush fire prevention strategies. And isn’t that very timely at the moment?

So I’m looking forward to doing more Collaboration in 2020 and especially in IoT where it really needs whole ecosystem to deliver a solution.

Successful Endeavours specialise in Electronics Design and Embedded Software Development, focusing on products that are intended to be Made In Australia. Ray Keefe has developed market leading electronics products in Australia for more than 30 years.

You can also follow us on LinkedIn, Facebook and Twitter.

This post is Copyright © 2021 Successful Endeavours Pty Ltd.