Design For Manufacture

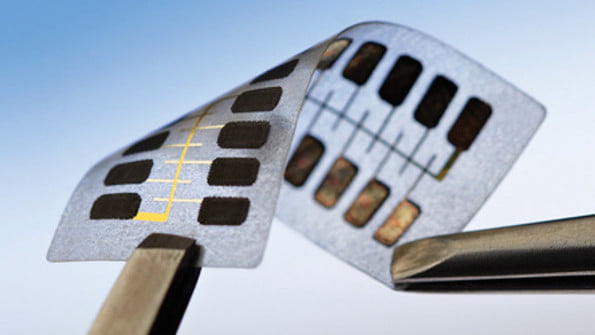

Electronics products almost invariably have a Printed Circuit Board , PCB, on the inside. This is one of the most common things we do, designing the Printed Circuit Board on the inside on the product. Now designing a Printed Circuit Board so it works correctly is one thing, but if you are going to make them cost effectively in volume then you have to consider the manufacturing options at your disposal. To achieve Low Cost Electronics Manufacture requires every aspect of the design to be considered.

So the things to focus on are:

- Use SMT as much as possible,

- Reduce the number of components by using more highly integrated circuits,

- Reduce the variety of components so the number of reels is reduced,

- Ask the PCB loader about their standard panel sizes. If you can adjust the PCB size to suit them then it will reduce their costs,

- Work with component types that the PCB loader can handle

- Work with components that you can buy in suitable quantities

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile at Ray Keefe. This post is Copyright © 2011 Successful Endeavours Pty Ltd.