Today we look at one of the Project Priorities Perspectives in action. This was a case where performance was the most important factor and so minimising cost or time to market was a lower priority in the this Electronics Manufacture project. In this case the PCB and electronics were Manufactured In Australia.

We were developing a wireless Data Logger product. We selected 802.15.4 as the wireless protocol but did not need the interoperability of ZigBee. A key issue here was Battery Life. One use of the product was as a device left in the field and collected after 1 to 6 months. The actual time interval depended on the use. Since we have the client’s permission we can share details of the project and the product with you.

The product is a Corrosion Protection Data Logger and the client is Borgtech. The first version is the Borgtech CPL2 and it is on the market today.

Some key product features made it a little tricky as an Electronics Design Project:

- inputs must withstand lightning strike impulses. This equated to 5KV for 2 seconds according to the local standards!

- wireless connection for both convenience and also as an OH&S safety measure

- 6 months battery life

- 60dB rejection of mains frequencies at 50Hz and 60Hz

- 10MOhm input impedance

- a good profit margin

Don’t worry if you don’t understand what all the details mean, I wanted to show how we used the process to identify the best approach rather than go further into millivolts and microwatts.

Technically, this project was quite a challenge. And a classic niche marketing example as well. My initial approach was to minimise the production component cost and look at ways to meet the other objectives. But it didn’t take long to realise that battery life was going to be the hardest challenge here. I was able to use digital signal processing techniques (software) to meet the mains frequency rejection but the power requirements meant we were never going to get 6 months battery life and the radio side also contributed to that problem. I’ll concentrate on the filtering problem.

Analogue Electronics to the rescue

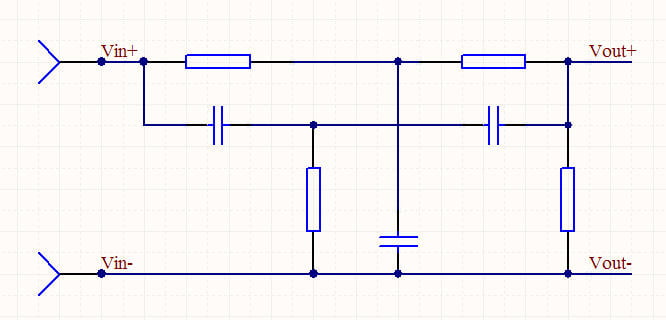

Normally we have been removing electronics components and replacing them with software to save on product cost. But this time, the priority was performance and not cost. So I added components instead. Below is a schematic representing the front end of the product.

Analogue Electronics Schematic

For those interested, this is a twin T filter. It is a notch filter that takes out specific frequencies. If you want more details then post a comment and I’ll add them.

The great thing about this is that it doesn’t use any Battery Power. Unlike the software solution which uses the whole power budget on its own. So from the batteries perspective, it is FREE! It did cost some design effort and did add some production cost but the battery got off lightly.

So here is how the priorities played out for this project. To get the performance, it cost a bit more and took a bit longer. The outcome was the right product at an acceptable price point and in a market with growing demand. Powerful stuff.

Now we did have to do a lot of other stuff to deliver this product so that it met every one of the design objectives. It also delivered on the client’s expectations and met the cost target too. It helped a lot that Borgtech understood their market and were able to guide us when making the decisions about priorities.

In practice, we make decision like the one above every day. Going left at the right time when everyone else is going right can deliver outstanding results. Marc Dussault refers to this as antimimeticisomorphism.

Next I want to look at going the opposite way to the path we took for this project. This is a case where cost is king and performance must be good enough but is not the primary priority.

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile. This post is Copyright © Successful Endeavours Pty Ltd.