In this post we will look at the Product Development Process and how to get improved outcomes. But first here is a fun graphic made from our logo.

Successful Endeavours – Making Electronics and Embedded Software Work

Product Development Process

The Product Development Process is intended to reliably deliver new products for manufacture or distribution. This is a critical component of a Product Strategy where you are creating the product rather than sourcing it from a supplier. So you would think that it should be a highly optimised, well oiled machine that reliably delivers successful products. Alas that is not always the case. With 30 years of experience in Developing Products for a wide range of industries I have seen my share of projects handled well and not so well. Here are some general principles I have gleaned from my experience in Successful Product Development Projects:

- Risks must be identified and managed. Track them and eliminate them as soon as possible.

- Anything clever or tricky needs to be checked by someone else.

- Everything else also gets checked. Design reviews, code walk-throughs and prototypes save time, money and heart ache later on.

- Hold the timeline. Foster an attitude that slippage is not acceptable.

- Test and check everything.

- It’s not finished until no-one has to do another thing to it.

So six core principles. They are inter related of cousre. Let’s look at how these work out in practice.

Successful Product Development Principles

Lets look at how each of these priciples can be used to improve the likelihood of a Successful Product Development Project.

Risk Management

Risk Management is an old idea. Not surprising since risks have always existed. Did you know that during the Manhattan Project it was determined that there was a chance that a fission bomb could ignite the whole atmosphere ? Having got contradictory reports the argument was eventually settled by a report showing that although it was possible, it was unlikely. How comfortable would you feel running that risk ? Fortunately the average Development Project is dealing with much more mundane risks such as achieving Technical Requirements such as:

- Power Consumption

- Unit Manufacturing Cost

- Performance Criteria

But the approach is still the same:

- Identify the risk

- Work out how to ameliorate the risk – reduce it – or eliminate it

- Do tests to confirm the risk has been dealt with

- Iterate until it is no longer a risk

Review the clever bits

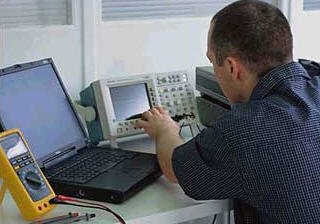

Test Everything – Clever Design Needs Test

Where possible, any particularly clever or tricky areas of the project need to be reviewed by someone not involved in the everyday work of the project. This is primarily to ensure that assumptions are challenged. If you can’t get an outsider to do the review, use a process like Six Thinking Hats by Edward De Bono which can allow team members to step outside their emotional and assumptive predispositions. Unchallenged assumptions are unmanaged risks.

Review the rest of the project

Review Everything

The astute amongst would have noticed that I am proposing everything gets reviewed. But the tricky bits get extra review. This section is for the regular bits. Reviews are an essential tool to find mistakes early and eliminate problems down the track. You don’t have to solve a problem you don’t have. Or as Jack Ganssle famously quipped “Skip Bugging To Speed Delivery”. That article refers to using Code Review and Design Review to find problems early and fix them so they don’t become much bigger problems later on. Imagine a scenario where a Software Bug causes an electric motor to try and spin backward every now and again and then corrected itself almost immediately. You would get a momentary shudder or jerk followed by correct motion and it would only happen every now and again. How would you determine that this was a software fault and where the fault lay? It could be symptomatic of any number of issues including Mechanical Design and Electrical Design. How about this similar real world case. I won’t mention the company, but their elevators had an Integer Overflow problem in the motor controller that caused the elevator to go in the wrong direction, about once a month, for half a floor. Very disconcerting to the passengers if they pressed up, and promptly dropped half a floor before then going up. Fortunately they found it and fixed it before it happened to someone at the top or bottom floor. All the Software Industry Metrics show for that for Software Development; Design Review, Code Review, Unit Tests and System Simulation save money and time. And yet in many projects they don’t happen enough or are done after the event as a Quality Assurance box ticking activity where they add mostly cost and little in the way of value. Lean Coding argues that you can reduce your Software Development Budget in particular by doing Code Inspections during the project as part of the Risk Management and Quality Management process. By reducing the bugging, you can reduce the debugging.

Stick to the Timeline

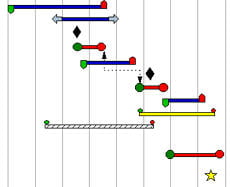

Project Development Timeline

An attitude that the schedule slipping is normal can be very costly. Some examples of how to avoid this are:

- Develop and Simulate the Software before the Hardware is ready

- Prototype early and thoroughly

- buy in IP where it makes financial sense – this can also reduce risk

- get expert assistance with areas outside your competence

- review regularly and honestly

As someone who has done a lot of team leading and project management, I have learned to ask about progress in more than one way. I find the following to be very common: Manager: “This module is estimated as 10 days of work to complete. How complete is it”? Developer: “About 80%”. Manager: “How many more days of work are required to fully finish everything”? Developer: “To fully finish everything, I would think 6 more days would cover it all”. The discrepancy is easy to spot. People estimate high on progress because they want to please. They also like to finish well so they tend to estimate conservatively on required effort. In practice the real answer lies somewhere between the 2 extremes. If the task had already consumed 6 days of effort then it is likely to run late. If you have ever built a house you might have experienced the knock on effect it has when one trades person doesn’t turn up and everyone else misses their scheduled action time because they are now waiting on a predecessor task, the trades person who has to come back again, before they can start their task. The same thing happens on projects. So fight hard to hold to the schedule. It is better to over resource a task (according to the plan) and get it done than to let everything and everyone slip which usually costs a lot more. Additionally, it is quite common that the later you are in the market, the lower the overall profit. So it is worth holding the schedule for this reason as well.

Test and Check Everything

Test Everything

This is another Risk Management related principle. Don’t assume it will be OK. Even if you have done it 100 times before, test it again this time. Make sure it really is OK. This ensures it really is 100% complete. This also implies that you are going to design things so they can be tested. Another principle. Design For Testability or sometimes called Design For Test. Do it. It will save you time, effort, money and sleep. Test Driven Development is another example of a Modern Development Methodology where you set up the test first then develop the product so it passes the test. If the Product Requirements change, you change the tests first, show that the old Product Design fails the test, then update the Product Design until it now passes the test.

It is not finished until no-one has to do anything else to it

Many tasks are called complete but they aren’t. The documents might be checked into the Revision Control System, also known as a Version Control System or Version Management System, but it isn’t complete until it is 100% tested, 100% integrated, 100% reviewed and 100% signed off and no-one has to do another thing. This also means that when tasks are identified that weren’t thought of in the original Project Plan, you then add them and don’t try and fiddle them into existing tasks. This is different to working out the fine detail of a task and realising it is under resourced or over resourced on the Project Plan. You also want the extra tasks visible on the Project Management Plan so when you do the next project you have evidence that they were required last time and can make allowances for them.

Trip Assurance for Developers

Satisfaction Guaranteed

In marketing, the term Trip Assurance refers to the client having a clear expectation of this transaction or experience being a good one, just like every other one has been. I think we can begin to develop some of the same as developers whereby projects can be routinely good experiences and likely to be so each time.

This post is also available as an eZine article with Expert Author classification.

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile. This post is Copyright © Successful Endeavours Pty Ltd.