Renewable Energy

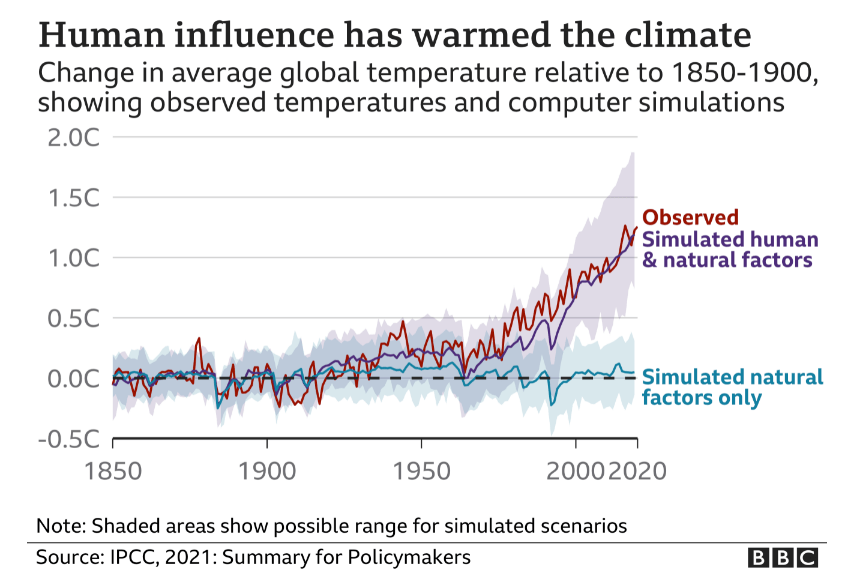

Regardless of where you sit on the climate crisis versus beat up continuum, generating renewable energy that doesn’t continue to create pollution post manufacture has a lot of merit. So where are we at now that it is 2023 and we are green house gas looking at pollution reduction targets over the next 12 years?

Better Solar Panels

Most of the best breakthroughs in solar cell efficiency in the past 20 years have come from the University of New South Wales (UNSW). So you would think we should be making the world’s best solar panels? Alas not, but I still think it is the right move and especially as China has shown it can play hard ball on trade restrictions when it suits them. A definite case for sovereign capability.

According to Renew Economy, there are 6 promising projects that could lead to either significant reductions in solar cells costs or a doubling of solar cell efficiency. These are:

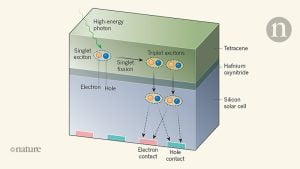

- singlet fission solar cells

- PERC/TOPCon Hybrid Cells

- Chalcogenide-Si tandem cells

- Reducing reliance on Silver

- Machine Learning to optimise solar farm management

- Material dependency reduction

The singlet fission project could increase the theoretical maximum efficiency of Silicon solar cells to 45% by creating double the number of charge carrying excitons generating 2 instead 1 as happens now.

You can read the full rundown at Six ways Aussie researchers hope to deliver ultra low-cost solar.

Grid scale storage

Currently, 95% of all the grid scale storage in the world is hydopower. Australia is the flattest and driest continent on earth (ignoring Antarctica which has 97% of all the fresh water in the world but it is frozen). So it would seem that hydropower is not as easy an option here.

An Australian government study shows that there are about 3000 identified low-cost pumped hydropower sites in Australia.

So that is a lot.

The other things that affects the cost is whether the water is potable (consumer grade clean water). So some sites can be made into closed systems and not necessarily connected to the main water supply. This reduces the cost of the facility.

And of course there is still the big battery and flow cell options for large scale storage. In practice there is not enough Lithium in the world to achieve this using that battery material so while Australia might get by if we stopped selling off ore to China and used it to build the batteries ourselves, it doesn’t solve the global problem and this needs a globally scalable solution.

Offshore Wind Farms

This one is a bit more controversial for a range of reasons. However it does mean the wind farms are not consuming nice coastal foreshore areas. Victoria’s Star of the South project will be built offshore from Gippsland.

So this is looking to be the beginning of a big shift in attitude as we all start to pull together for the good of the whole planet.

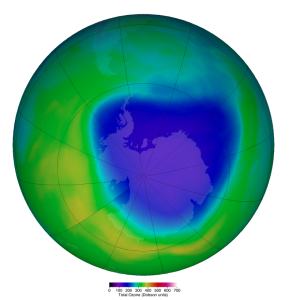

Ozone Hole Repair

As a sign of hope, the actions taken by all countries 30 years ago to ban the use of CFCs so that we stopped damaging the Ozone Layer have now shown that they were successful. The Ozone Layer is repairing itself and we could see it fully repaired by 2050. So unilateral action can work. Giving us hope in the area of climate repair.

This has reduced from a peak of 27.5 million square kilometers in 2006 down to 23.2 million square kilometers in October 2022. Part of the problem is that CFCs have very long half life times of up to 500 years so this is a slow process. CO2 has a half life of 120 years so this is why we want to stop adding more of it to the atmosphere as soon as we can. You can read the full report at Ozone Layer Hole Update NASA.

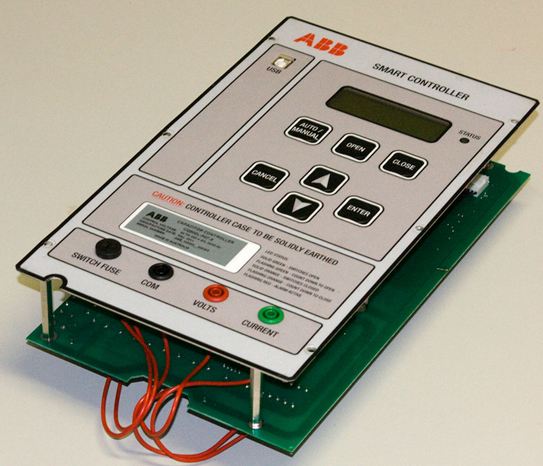

Successful Endeavours specialise in Electronics Design and Embedded Software Development, focusing on products that are intended to be Made In Australia. Ray Keefe has developed market leading electronics products in Australia for more than 30 years.

You can also follow us on LinkedIn, Facebook and Twitter.

This post is Copyright © 2023 Successful Endeavours Pty Ltd