The 4th Industrial Revolution

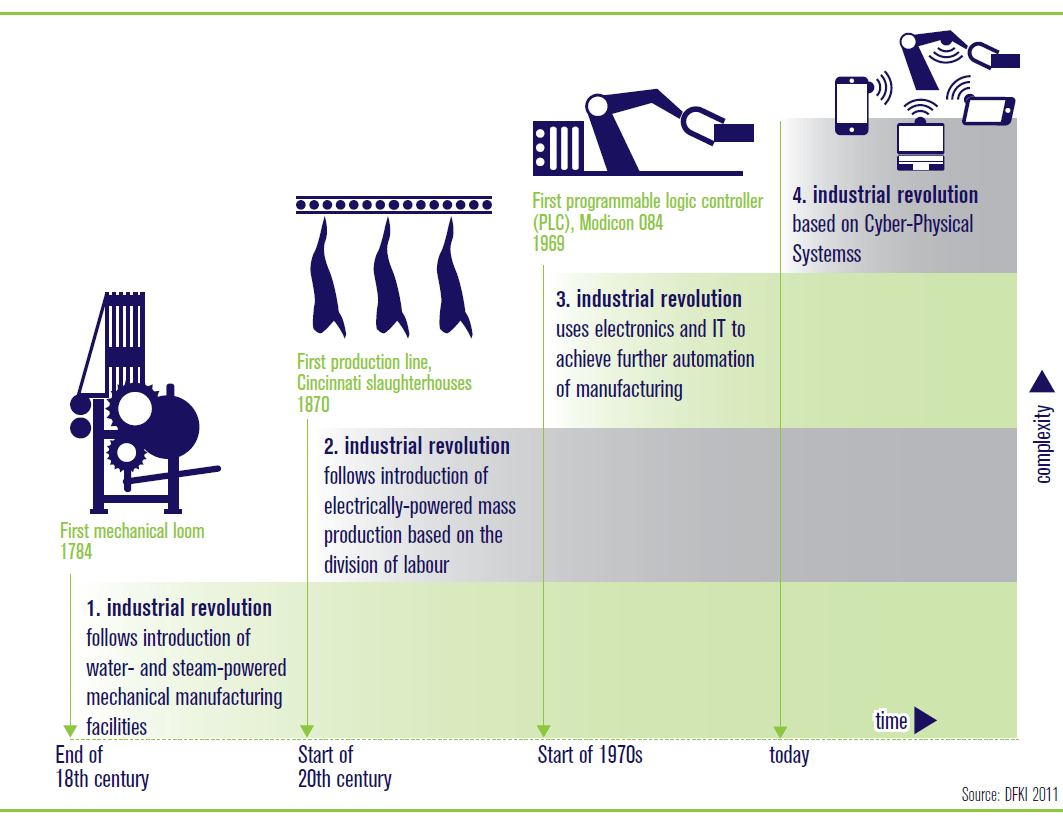

This is the first in a series of posts looking at the 4th Industrial Revolution that is now upon us. To understand why this is a big deal, it is worth looking at the previous 3 Industrial Revolutions.

This material is based on presentations made by Dr. Martin Schlegel who is a consultant providing regular updates to the South East Business Networks as well as working with overseas organisations working in this area. He even has clients in Germany.

Industry 1.0

This is the first of the mechanical automation to create a huge breakthrough in productivity and consistency of production. The earliest examples are steam and water driven textile mills and weaving machines. These completely change the way cloth was produced in the 1800s.

Industry 2.0

This is the production line. Now you might immediately think of Henry Ford here, but he was not the first by a long shot. Early examples are meat production moving away from chopping blocks where all of an animal was butchered to a line where at each station a different step of the butchering took place.

Regardless of the example, the modern production mass volume technique was now in play.

Industry 3.0

In the 1970s the advent of computers and PLCs meant that production lines could be controlled by IT systems. And with Electric control for many processes this allowed automation of production activities at an unprecedented level. With QA systems and the ability to do automated inspection you could guarantee quality at very high production rates. This dropped the unit production to lower levels than was possible in the past.

And this is as far as many have gone.

Industry 4.0

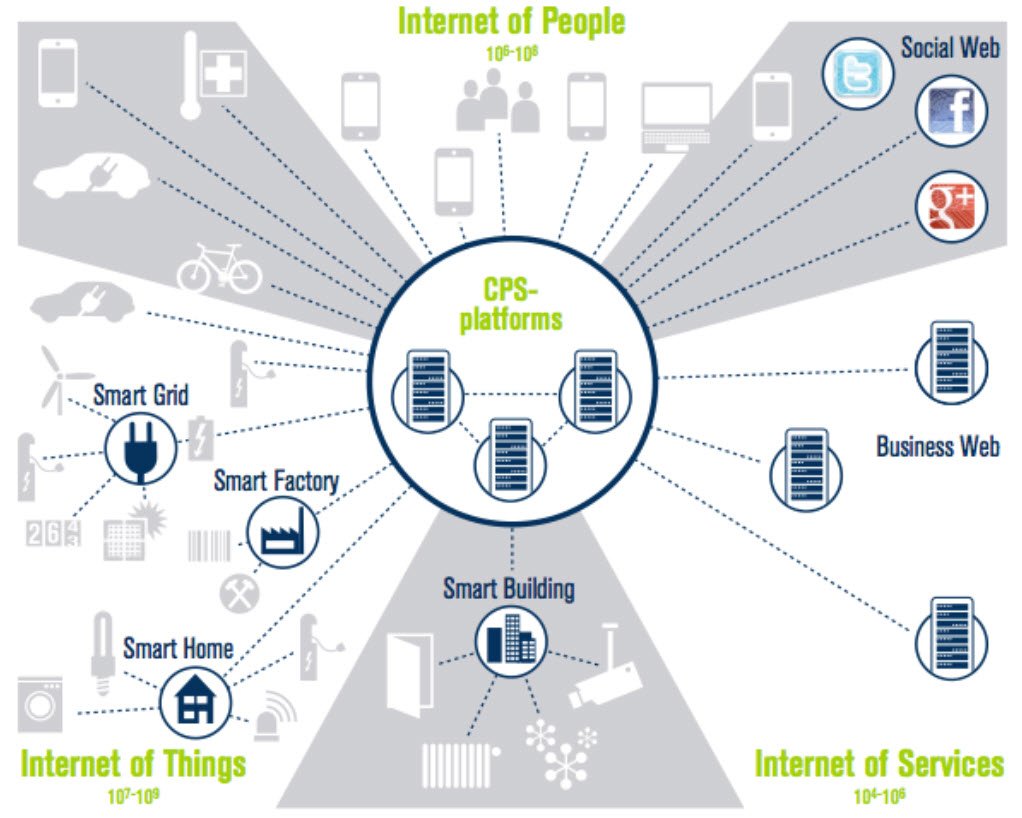

We have smart machines, sensors that communicate, high data rate wired and wireless networking and a range if identification technologies including optical and RFID. If you put that together with Industry 3.0 automation and IT systems you can now have Mass Customisation. Industry 3.0 focused on high volume, low mix, high quality manufacture. Industry 4.0 takes that and adds high mix, self maintaining machines, automated order to delivery scheduling and the ability to create reliably customised product just as readily and cost effectively as Industry 3.0 ensured reliable quality of high volume products.

Although Europe, and Germany and Switzerland in particular, have been looking at this for 15 years now; the difficulty with getting the language clear and the benefits obvious shows that we are still in the emergent phase. The Cincinnati meat processors might have shown the world what was possible in the late 1800s, but adoption took time. The adoption time will be less with this next revolution because of modern technology but it will still take a while for us to fully comprehend the advantages and to establish best practice. The biggest change will be in our thinking.

And Dr. Martin Schlegel‘s top 6 tips for Australian businesses wanting to capitalise on Industry 4.0 are:

- Transform into a service manufacturer

- Merge Industry and Internet Culture

- Open Innovation and Collaboration

- Develop new Business Models

- Focus and Set Priorities

- Value Security and Customer Privacy

We will look at several of these more closely in future. I’ll leave you with the Bosch presentation on implementing Industry 4.0 and the Internet of Things.

Successful Endeavours specialise in Electronics Design and Embedded Software Development. Ray Keefe has developed market leading electronics products in Australia for nearly 30 years. This post is Copyright © 2015 Successful Endeavours Pty Ltd