Industry 4.0 and Bosch Australia

This is the first of a two part post covering the SEBN (South East Business Network) business breakfast just before Christmas 2016. The first speaker was Gavin Smith of Bosch Australia. His talk was title “Life After Auto” and here is my summary.

In the 1960s you could make anything in Australia because the import tariffs were high and we were a long way away from the rest of the world. But by 2008 all that had changed. Although Robert Bosch is the largest tier one automotive supplier in the world, and the largest automotive company that doesn’t assemble vehicles, the original Bosch Australia factory is no longer there and a new one built and they are about to expand again.

So there is a lot of change. He also quoted Jack Welsh of GE fame: “If the rate of change on the outside exceeds the rate of change on the inside, the end is near!”

High volume no longer has to be a lot of the same thing. They are now doing high mix electronics manufacture and are about expand that as they have run out of capacity. This follows the Industry 4.0 model rather than traditional manufacturing. The design team is also expanding s they are now do bespoke product design with the intention of making them locally.

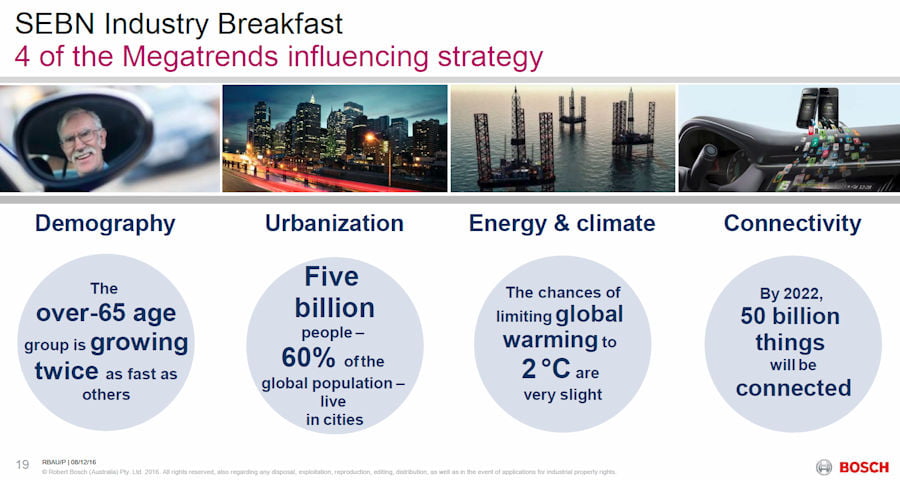

Bosch are also keeping track of the following Megatrends:

- Demography

- Urbanisation

- Energy and climate

- Connectivity

And all of this relies heavily on IoT (Internet of Things) devices and Big Data. To be a global supply chain player or to have a modern product you will have to have connectivity and visibility of every part of your process and your supply chain as well. And for Industry 4.0 you will especially need it for inside the factory. This is already happening.

Robert Bosch are also looking at incubation for new ideas internally and also externally. This is a great idea and something we are also doing with both clients and prospects.

They are also looking to attract more women into STEM (Science, Technology, Engineering and Maths). Something I am also keen to see happen.

Industry 4.0 example

Gavin finished with a video that showed just how streamlined the Design to Manufacture path could become. Something essential to the realisation of a true Industry 4.0 mass customisation.

[This video is no longer available]

While it is worth remembering that some of the above is a view of how the Industry 4.0 future could be, rather than what today looks like, Europe have been pursuing this trend for 15 years. So we have quite a bit of conceptual catching up to do as well as implementation capability. And we need to start early which is why the Casey Tech School project and Schools of the Future are so important.

Successful Endeavours specialise in Electronics Design and Embedded Software Development, focusing on products that are intended to be Made In Australia. Ray Keefe has developed market leading electronics products in Australia for more than 30 years. This post is Copyright © 2017 Successful Endeavours Pty Ltd.