Component Selection

We have worked our way through Requirements Capture and Technology Selection. After doing some initial design work and deciding on how the circuit will work, you have to find components that you can buy on a reasonable lead time and at a reasonable price. This depends a lot on the expected production volume because if the volumes are low then you might not be able to secure the components you prefer.

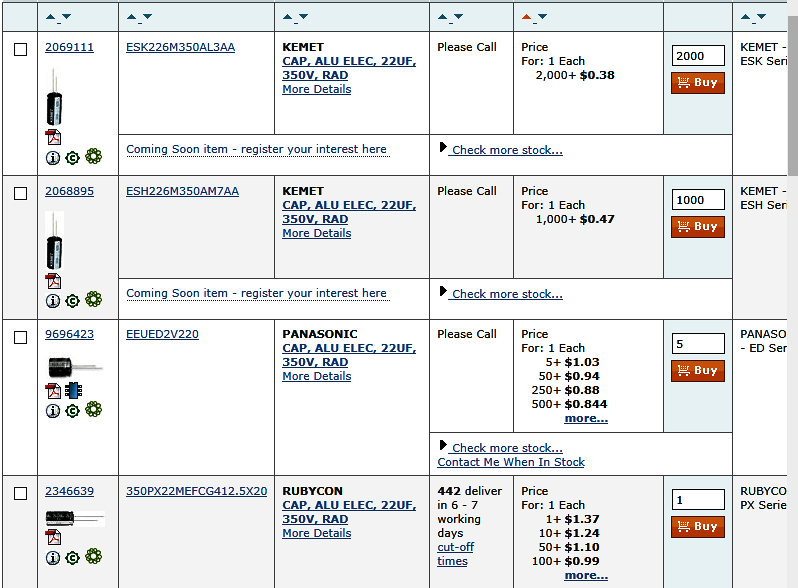

For products Made in Australia, the typical production volumes are less than 5000 units per annum. Products in this category are niche or low volume products and are generally defensible internationally because of the special and targeted nature of the products. But it does introduce a complication. You don’t have much of a bargaining position with suppliers. In this circumstance you often have to look at what you can buy and from who. This will involve looking at both local distributors and international sellers of components. An example from Element 14 is shown below for options for a 22uF 350V radial leaded capacitor:

And once selected, you might have to go through this exercise for each subsequent production run. Whereas much higher volume products can negotiate forward schedule orders and secure components in advance of their being required. So each product and production run needs to be handled according to your specific circumstances.

External events can also influence component availability. As an example,after the 2011 earthquake in Japan there were many components that were in short supply for up to 6 months.

This is one of the things you look for in a Niche Electronics Manufacture supplier, the ability to handle the component selection not only for the first production run but for subsequent runs.

Successful Endeavours specialise in Electronics Design and Embedded Software Development. Ray Keefe has developed market leading electronics products in Australia for nearly 30 years. This post is Copyright © 2014 Successful Endeavours Pty Ltd