Electronex 2024 – Celebrating Australian Electronics Manufacturing

This year in Sydney we are again celebrating Australian Electronics Manufacturing at Electronex 2024.

We are exhibiting at stand B22 and I will be giving 2 of the free seminars covering:

- Selecting A Wireless Communications Technology

- Onshoring Your Electronics Manufacturing Back To Australia

These will both be practical “how to” sessions with examples and case studies.

And this is a particularly significant year for us as we are still designing electronics products that are intended to be Made in Australia, but we now have a Electronics Manufacturing factory of our own. We are not trying to take business from the already existing and excellent Australian Contract Electronics Manufacturers (CEMs) but we are looking at supporting the early stage and small scale clients who don’t yet have a significant volume of business. As well as significantly improve our Electronics Prototyping capability for the R&D projects we undertake.

Which also means we are now signed up to the Australia Made campaign in the Australian Made and Owned category!

Australia Made And Owned

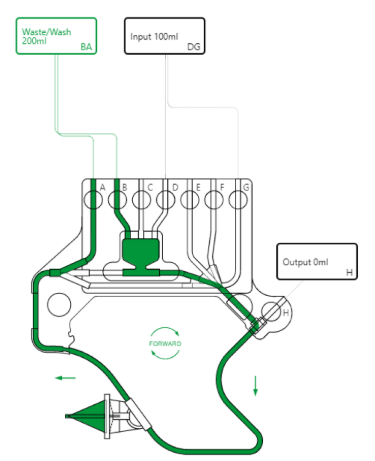

You can check out our new SMT line in action at Automated SMT PCB Assembly with a video of our new line in action.

SMT Automated Assembly – Our own line in Action

We are hoping you can drop in and say hello to us at Stand B22 at Electronex 2024 and also see some of the other excellent Australian suppliers and manufacturers who will also be there as one of the more than 90 Electronex 2024 Exhibitors.

Electronex 2024

Successful Endeavours specialise in Electronics Design and Embedded Software Development, focusing on products that are intended to be Made In Australia. Ray Keefe has developed market leading electronics products in Australia for more than 40 years.

You can also follow us on LinkedIn, Facebook and Twitter.

This post is Copyright © 2024 Successful Endeavours Pty Ltd