This continues our review of the Project Priorities Perspective. See the Project Priorities Perspective post for the concept behind this and Time and Cost versus Performance and Time and Performance versus Cost for a look at those trade offs and how they affect Low Cost Electronics Manufacture in Australia.

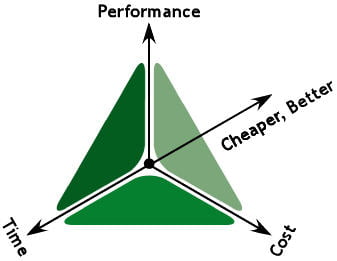

Here is a visual view of this set of electronics manufacturing trade offs:

Project Priorities Perspective – Performance and Cost versus Time

The previous two perspectives looked at cost and performance and their effect on the other priorities. This one looks at time. Time is a two edged sword. It is easy to spend but hard to save.

Here are some of the trade offs that affect time:

- if you spend more time, you can get the unit cost down or the performance up

- if you reduce features or performance you can have it quicker

- if you spend more time you can often select and use less expensive resources

- to get it quickly, you usually have to buy in either IP or specialised expertise

- being later to market usually reduces your profit

- being early to market usually increases your profit

- doing it right the first time saves time

- increasing production automation decreases production cycle time

So this is more straight forward than the other perspectives. To get it faster, you have to either reduce features and performance, or buy in specialist IP or expertise. And if you can wait longer, then you have more choices for how you go about it and can either increase the features, improve the performance or reduce the cost.

So this wraps up this very cursory look at the Project Priorities Perspective. It is a powerful tool that is easy to apply and can dramatically improve your results. The key, is that it makes you think about the priorities and what outcome you are really after. At the end of the day, if you aren’t clear about your outcome, then you don’t have a basis to plan or succeed.

Next I will be looking at some practical project tips for increasing profits and some surprising ways to improve performance. And you have probably already worked out that you can apply it more than just Electronics Manufacture in Australia. You have, haven’t you?

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile. This post is Copyright © Successful Endeavours Pty Ltd.