How Green is my iPhone?

Have you ever wondered just how green an iPhone really is?

Today’s blog post was sent to me by Dr Marc Dussault, The Exponential Growth Strategist. It’s an Infographic taken from DailyInfographic.com. At Successful Endeavours, we’re always interested in recycling and sustainable technologies and solutions. You will have seen some of that is past posts on how to be greener with the Electronics Design including Electronics Design for Green Manufacture? , Green Electronics Strategies Reduce Power While Awake and Green Electronics Strategies Sleep Saves Energy .

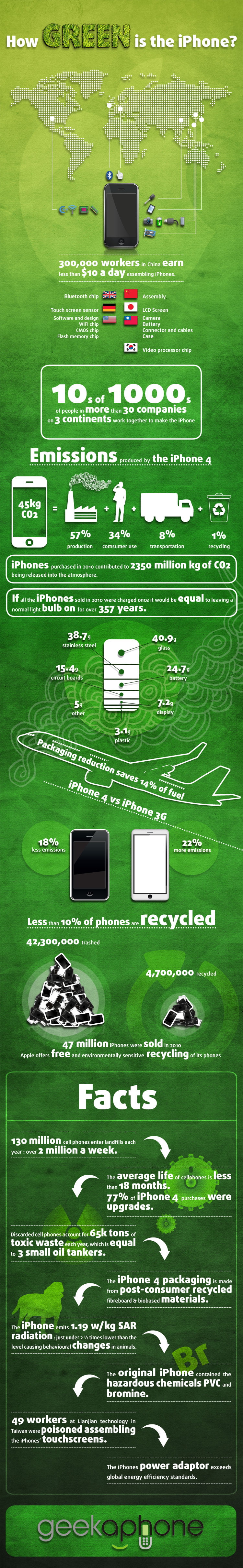

For this post we will use the infographic to specifically look at how GREEN the iPhone 4 is versus the iPhone 3G from the perspective of the production, use and disposal of the phone. Some key figures I noted or calculated are:

- Production Emissions are 57% of all emissions in the iPhone 4 product lifecycle

- 58.9% of the weight of the iPhone 4 is in materials that are easily recycled

- Packaging Reductions save 14% in transport fuel

The Packaging Reductions are an excellent example of simple things we can all do to save on emissions. And Apple offer a full recycling service that is aimed at being environmentally friendly which is also a great thing to put in place.

Electronics Manufacturing Energy

The area that stands out for me is the energy that is consumed in production of the iPhone 4. This is not an iPhone 4 specific problem but a general problem for Electronics Manufacture. If we want to talk about Green Electronics, then this has to include not just the product we use and the Electronics Waste and Recycling / WEEE, but we also have to get to the point where the Production Emissions, the energy to produce a product, is way less than the energy to use the product. This is a huge issue for Battery Operated Products, such as the emerging Electric Vehicle market, where the Production Emissions for just the battery can be close to half of all the Production Emissions.

Enjoy the infographic from the dailyinfographic Keeping it Green.

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile at Ray Keefe. This post is Copyright © 2011 Successful Endeavours Pty Ltd