Plastic Semiconductors

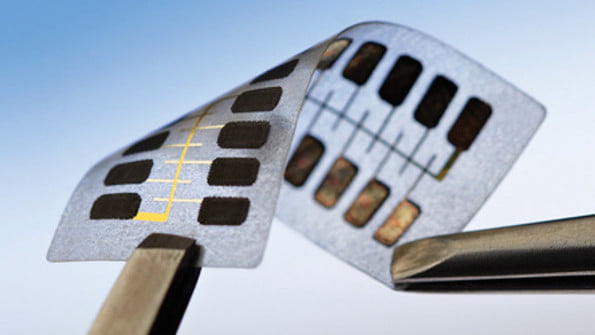

In a previous post on Printed Electronics we looked at new product opportunities that were being created using new fabrication techniques for semiconductors. But advances are also being made that benefit both conventional or new product concepts. In The Plastic Processor we get an insight into how you can make a microprocessor using Organic Transistors on plastic film.

The steps look simple, as is often the case on the other side of Research and Development for a new concept:

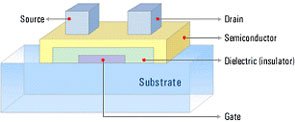

- the substrate is a plastic film with similar mechanical properties to cling wrap

- print a layer of gold to make electrical connections

- place an plastic on top of that to make the dielectric

- print a layer of gold to make electrical connections

- the organic semiconductor goes on top

And the circuit is complete. And at less than 10% of the cost of doing a similar process using Silicon. And of course there are variations on that theme. And better approaches will be developed rapidly now that a first successful attempt has been made.

Of course there is still a lot of work to do on getting the reliability and reproducibility up to the levels we expect from Silicon Semiconductors but this is a significant step forward.

And in the latest news, The Plastic Processor, we get an insight into how you can make a microprocessor using Organic Transistors on plastic film. This is certainly getting more interesting quickly.

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile at Ray Keefe. This post is Copyright © 2011 Successful Endeavours Pty Ltd.