What is a Prototype?

A Prototype is done in order to explore some aspect of a new opportunity without having to fully commit to it yet. Prototype has a number of potential meanings including:

- the original or model on which something is based or formed

- someone or something that serves to illustrate the typical qualities of a class; model; exemplar

- something analogous to another thing of a later period

- biology. an archetype; a primitive form regarded as the basis of a group

So a Prototype is either an early model or a smaller scale development to test a new idea.

Why Prototype?

So for engineering, we Prototype to reduce risk, and we learn from Prototypes to improve the likelihood of project success by being better informed for the next round of design. So a Prototype is a core Product Development Process Risk Management strategy.

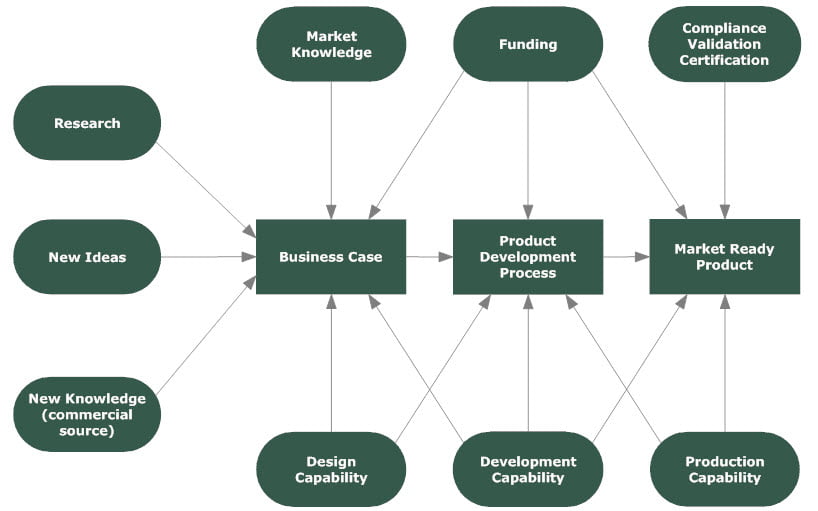

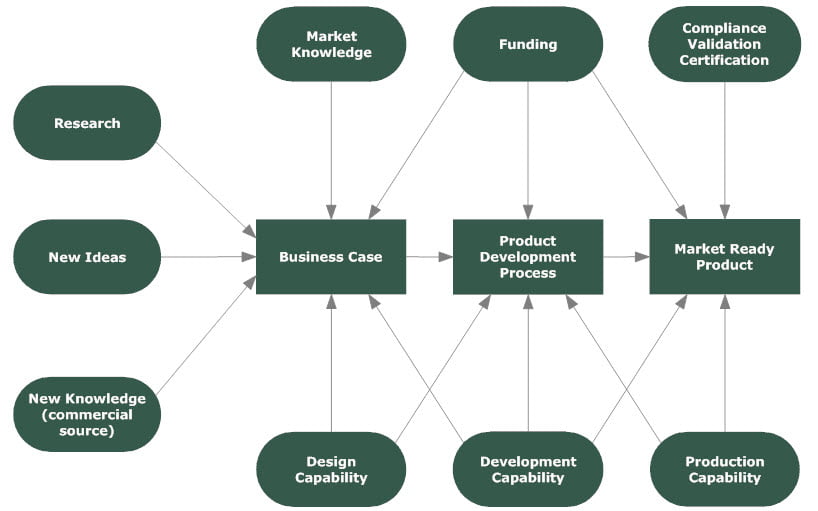

Product Development Process

A Prototype can also reduce other risks such as financial risk or market risk and isn’t always done for technical risk reasons.

Financial risk can be managed by breaking a project up into a series of stages and only committing funds to a stage when its predecessor has been successfully completed. A Prototype is often done ahead of a major block of Product Development to test whether the technical approach is likely to succeed and provide early warning of unexpected problems or interactions.

Market risk can be managed by trialling a new product idea with a smaller group of candidate customers to gauge their acceptance of the product. This has to be well managed however as history has shown that this approach, especially in the case of focus groups, can often just elicit the outcome the company hoped for and not a real example of how the market will react. Just look at all the failed Coca Cola new flavour launches.

And of course, technical risk can be managed by making Prototypes that implement the highest risk features as early as possible. We covered this in Improving Product Development.

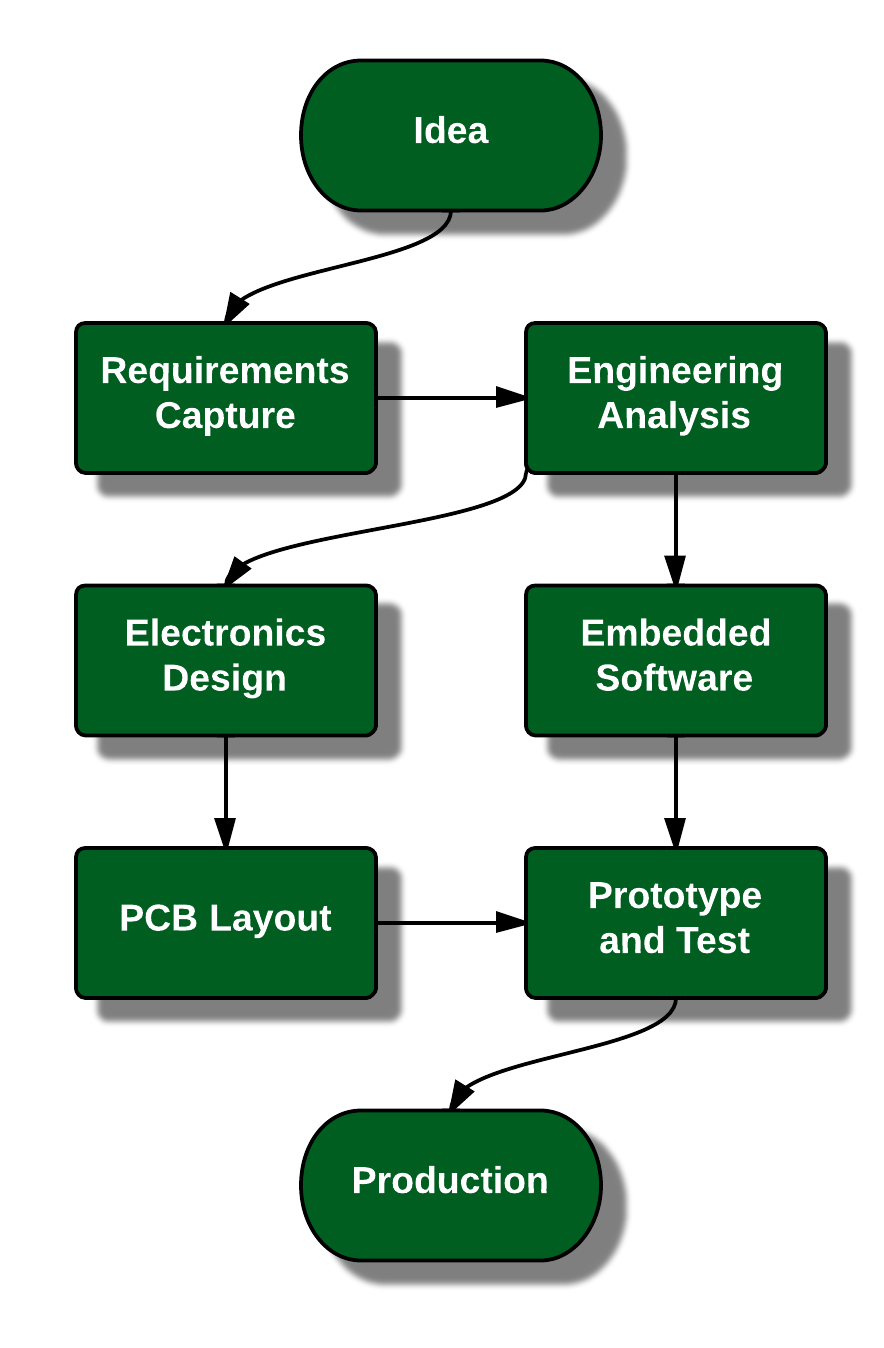

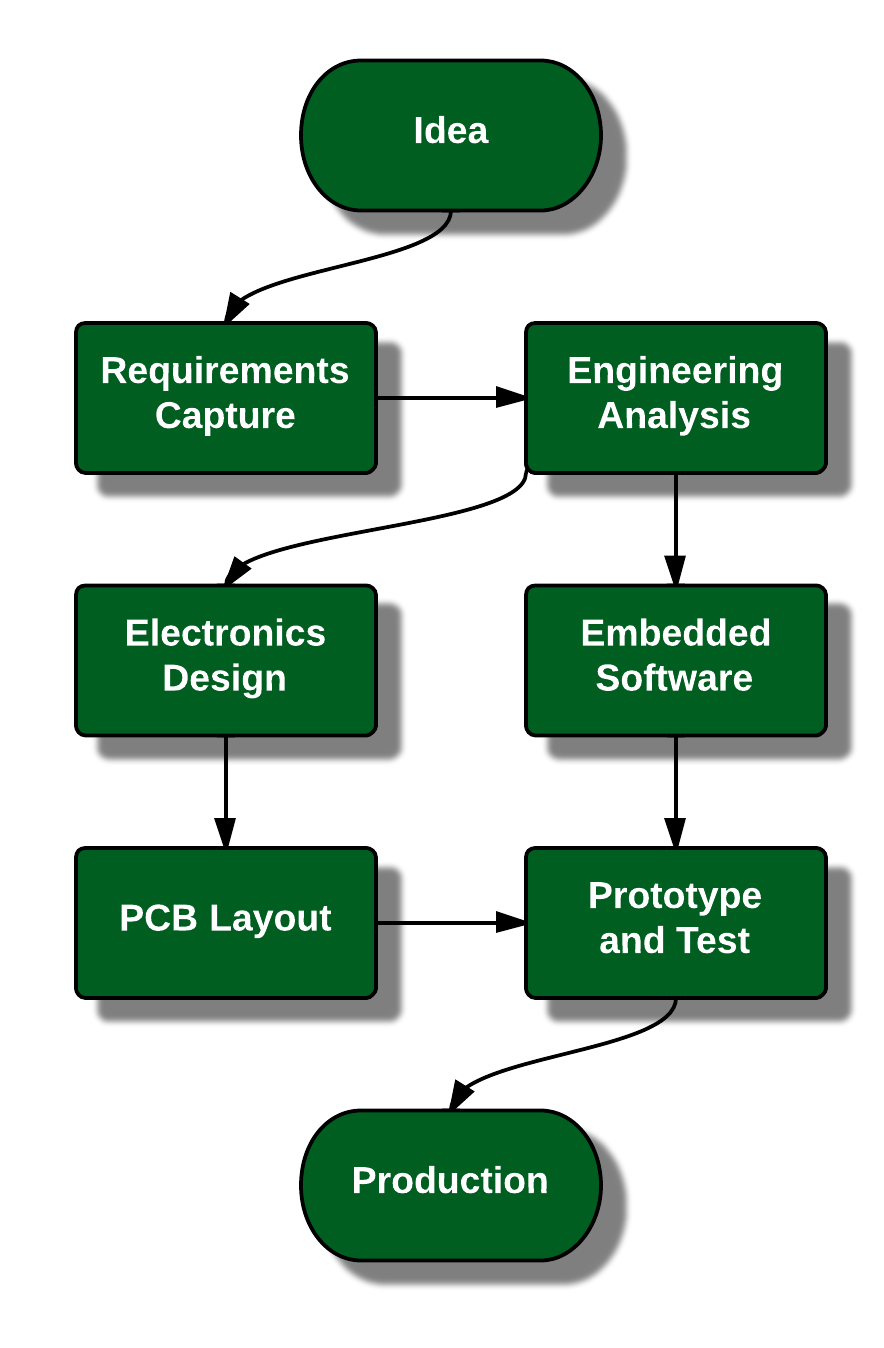

A Prototype can often be used during Engineering Analysis in order to evaluate the effectiveness of different options for addressing the Requirements. This is covered in Electronics Design Process.

Successful Endeavours Development Process

And then having designed a product it is normal to build a Prototype to ensure the final solution works as expected. This manages the risk that production tooling might need rework or even redesign.

How to Prototype?

This depends on the problem you want to solve. For this section we will focus on technical risks. A Prototype is very useful to allow you to measure some essential elements of the final product without committing to a final solution. So you can explore:

- modelling a problem and simulations

- noise and interference

- power consumption

- performance versus cost (compare several different prototypes)

- responsiveness

- system resources required

- hardware versus software solutions

- temperature rise

- materials properties

- shape and usability / ergonomics

- fit (especially PCBs in mechanical housings)

- …

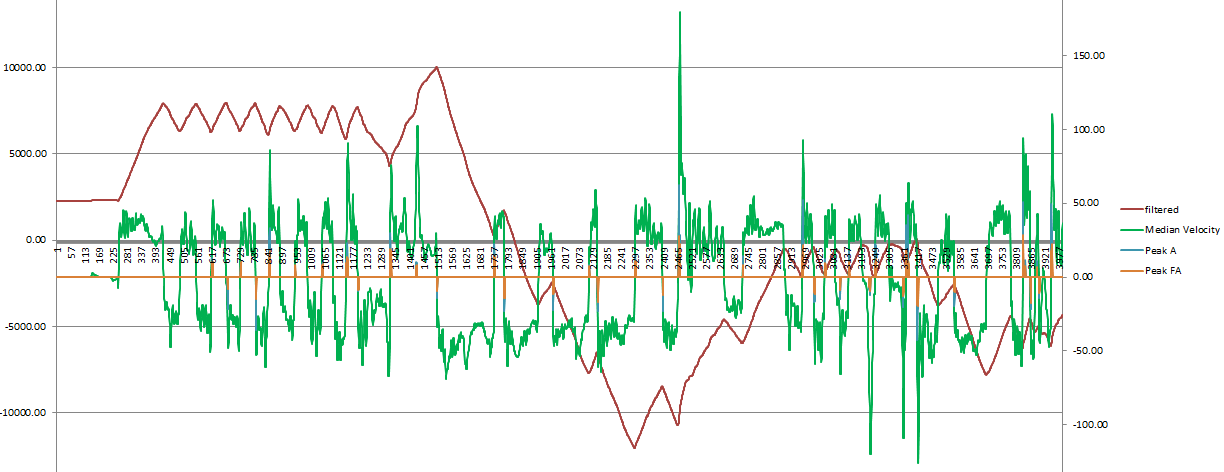

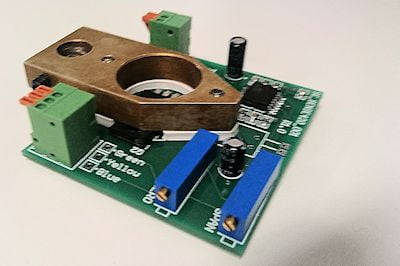

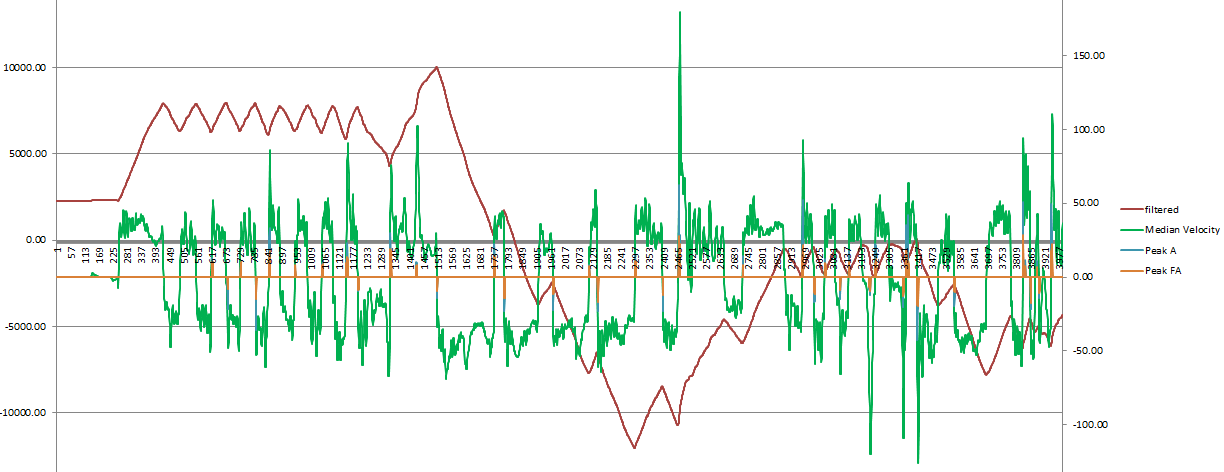

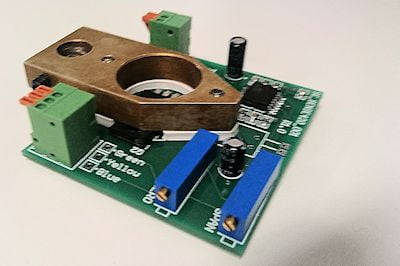

And the list can go on. The key is to determine where the risk is and manage that. In Project Management Pre-preparation we looked at using a Prototype to reduce both technical and financial risk at the same time. In this case, other developers hadn’t been able to produce a working product so the client had a clear risk to manage. And our approach was to make a jig that allowed us to explore the sensing that was needed and get real data to then analyse and develop a solution. The same jig allowed the solution to then be tested before we designed the Electronics PCBs and Embedded Software needed for the final product. And the client was able to authorise each next level of expenditure with confidence based on us having delivered against the requirements for the previous stage.

Simulation

And of course, 3D Printing for Electronics has enormously expanded the possibilities for mechanical prototypes by allowing anyone to quickly build and test the fit of objects together. It is also a viable option for low volume manufacturing.

3D Printed Spacer

3D Printed Spacer Fitted

Successful Endeavours specialise in Electronics Design and Embedded Software Development, focusing on products that are intended to be Made In Australia. Ray Keefe has developed market leading electronics products in Australia for more than 30 years. This post is Copyright © 2017 Successful Endeavours Pty Ltd.