This continues our review of the Project Priorities Perspective. See the Project Priorities Perspective post for the concept behind this.

This is the easiest of the the trade-offs to appreciate. If you want it quickly and it has to be good, then you are going to pay more for it. This doesn’t mean you shouldn’t shop around for the best price you can get, it just means that all things being equal, the cost for this trade-off will tend to be higher.

There are several ways this pans out:

- you can buy in technology or expertise to save time or improve performance

- you can use less tooling or automation to decrease the time to market

- you can hire more experienced or qualified staff

- you can use a more expensive technology

- you can partner with another business to spread the workload

There is overlap between these possibilities and several may be required to achieve what you are aiming for.

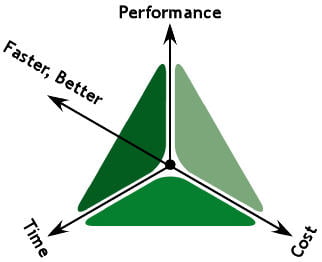

Here is the visual representation for this scenario:

Project Priorities Perspective

Now cost is a complicated trade off because there are many contributors to cost and their impact is felt in different phases of the project. For instance:

- buying in technologies tends to happen up front and is an early cost contributor

- creation and tooling costs are amortised over the production and so dissipate slowly

- staffing costs also happen up front

- production unit costs can be reduced by tooling and automation

- reducing tooling and automation increases rework

- tooling and automation cost up front and increase time to the first production unit

- short cutting development effort can increase production and warranty costs

- component costs can be reduced with creation or tooling costs

- warranty and maintenance costs happen after production

- maintenance costs can continue on past the selling life of the product

- more expensive technologies can be better proven and so quicker to implement

- more expensive technologies can provide better performance in the same development timeframe

- another business can reduce your time to market but you will share some of the profit with them

- being late to market can eliminate the profit all together, the ultimate cost

And estimating costs can be difficult. Particularly downstream costs like market entry delay and ongoing maintenance and support costs. See our recent post on Strategies To Be More Profitable for a more detailed look at the contributors to the Total Cost Of Ownership of a product.

But in general, selecting the right technology, the right team and the right supply chain will give you the greatest likelihood of getting to where you want to be, when you need to be there.

So who are you going to partner with to ensure your next product comes to market on time and on specification?

Next up we will look at getting to market faster while reducing cost.

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile. This post is Copyright © Successful Endeavours Pty Ltd.

________________________________________________