2025 stepping up

The start of a new year might be an arbitrary moment in time but it instills a sense of things moving forward. There are still plenty of problems to solve and opportunities that come from those solutions and we are choosing to look at 2025 through that lens.

So what are the opportunities?

IEEE Spectrum

IEEE Spectrum has provided a list of 9 Intriguing Engineering Feats for 2025 and that is a good place to start. I’ve cherry picked a couple.

Tracking Greenhouse Gas Emissions

MethaneSat is set to make global real time Methane Emissions publicly viewable. This is a big deal because Methane (Ch4) has a much bigger impact on atmospheric warming and is also increasing at a faster rate than Carbon Dioxide (CO2). Plus it is generally recognised that it is highly under reported. So this will help with the last problem and hopefully lead to reductions.

Radioactive Waste Cleanup

Radioactive Waste has been leaking into the soil at locations used for nuclear bomb development sites. So it isn’t just sites bombs were dropped on or where there have been nuclear reactor leaks. A bigger problem than I realised.

It is hoped that cleanup efforts will start to produce real results in 2025.

Energy Storage

This one did not get a mention but it is at the top of my list for 2025. Cleaner energy production and use requires us to get away from polluting energy generation. And while Nuclear Power is a candidate, that it is a long way off and there is a lot of energy expended and industry development to build it in the first place. I’m not worried about waste management because that is a solved problem. We just need a more mature conversation about how that can work.

So looking at the other options, here are the challenges and possible responses that I see.

Pumped Hydro Energy Storage (PHES)

95% of all the energy storage in the world is currently pumped hydro. But those are big projects and if the water has to be potable (drinking quality) then that also makes it more expensive.

Plus Australia is the flattest continent and low on water. Regardless of that Arena has published a survey that identifies 22,000 viable pumped hydro sites in Australia with up to 67,000GWh of energy storage. While the focus seems to be on big project like Snowy 2.0 there is clearly a lot of opportunity for smaller projects. See below for where the sites are. Access the full report at An atlas of pumped hydro energy storage.

Pumped Hydro Energy Storage Australia

Gravity Well

Pumped Hydro Energy Storage is a Gravity Well energy storage method. The water is the weight and pumping it up and letting it flow back down are the use of gravity where the height difference allows potential energy (storage) to be converted to electrical energy (generation).

But you don’t have to use water. And there are advantages in not having to maintain assets that stay wet all the time. So while the lack of mountains and height differences in Australia also affects this there are still plenty of options.

The most obvious one is to take all those mine sites that were never rehabilitated by the mining companies (in contravention of their licenses) and rig them up with generators and hoists and lug weight up when we are storing and let it run down when we are generating. Same as pumped Hydro only dryer. The weight can be anything including the mine tailings that might still be lying about.

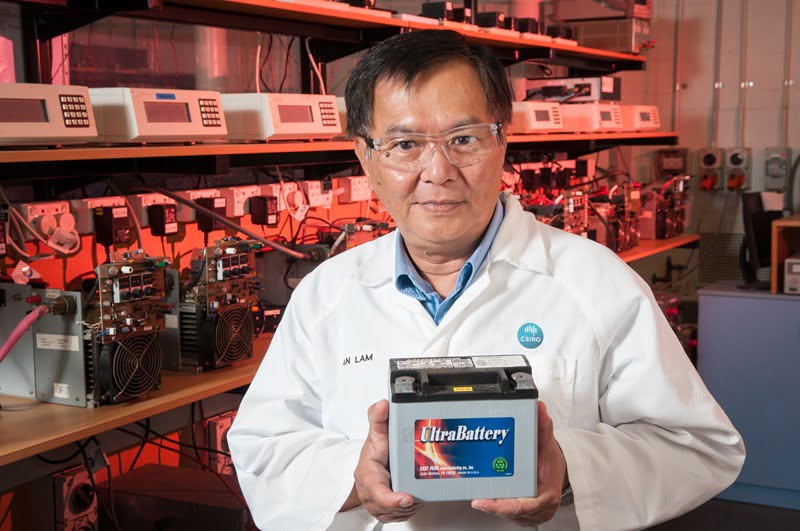

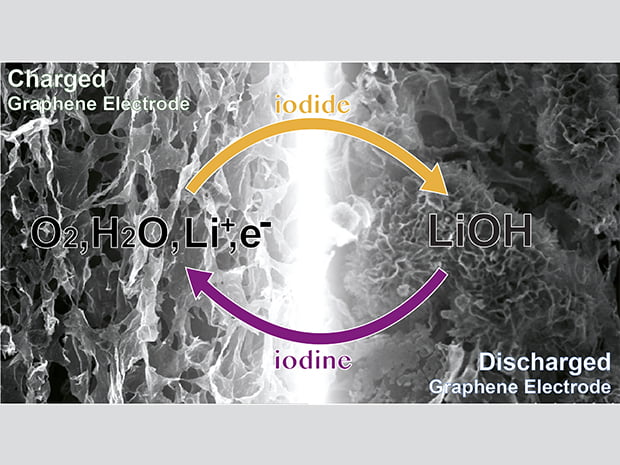

Big Battery

Alas, as far as we know it, there is not enough Lithium on the planet to provide all the storage we need. So this category needs to be broader than just Lithium. There is some excellent development in Sodium based batteries and Flow Batteries should also be in consideration.

Then there are liquid metal and molten salt batteries being developed. In practice, we might find ourselves spoiled for choice.

Thermal

There are lots of options here.

One of our clients, RAYGEN, uses solar mirrors to heat up water then uses the heat later on for generation.

RAYGEN Solar Thermal

There are overseas projects looking at heating up sand for storage.

So I remain optimistic that 2025 will see some important progress toward a more sustainable future.

Successful Endeavours specialise in Electronics Design and Embedded Software Development, focusing on products that are intended to be Made In Australia. Ray Keefe has developed market leading electronics products in Australia for more than 40 years.

You can also follow us on LinkedIn, Facebook and Twitter.

This post is Copyright © 2025 Successful Endeavours Pty Ltd