Carbon Nanotubes replace Solder Pads

Recent breakthroughs in nanotechnology could change the way Printed Circuit Boards, PCBs, are made and this could start happening soon. If you either the Design PCBs or Manufacture PCBs then you will want to keep up with this new technology that uses Nanotape PCB Pads.

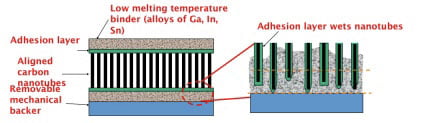

Here is a picture showing how the NanoTape structures differ from conventional Solder Pads. Although they look the same from the outside, the internal geometry shows the higher thermal and electrical conduction created by the Carbon Nanotubes. This can significantly help in product miniaturisation and for high power designs where both the enhanced thermal and electrical performance will improve the efficiency.

Like all new technologies, there will be teething problems but this has the potential to overcome the Tin Whisker issues that plagued PCBs before the introduction of Lead to Solder and which have emerged again with the move to RoHS compliance and the use of Lead Free Solder.

Ray Keefe has been developing high quality and market leading electronics products in Australia for nearly 30 years. For more information go to his LinkedIn profile at Ray Keefe. This post is Copyright © 2011 Successful Endeavours Pty Ltd.