Professor Goran Roos

Professor Goran Roos

As well as being the Thinker in Residence for South Australia, Professor Goran Roos is considered one of the 20 most significant thinkers of the 21st Century. This morning he was presenting his views on Australian Manufacturing to a combined breakfast meeting of the South East Business Network and SEMMA.

So what did I learn?

Here is the short list on what manufacturing does for an economy:

- R&D is driven by it

- Innovation is primarily manufacturing related

- Value added exports are usually manufactured

- Creates more indirect jobs per direct job than other sectors

- Many service companies have a manufacturing core

- Is the fastest knowledge growth domain

- Is essential for a highly competitive economy

His primary point is that “A healthy manufacturing sector is a must for any advanced economy with ambitions to maintain both economic and social wellbeing“.

Now he has my attention big time. Because this is something I have inherently believed my entire working life. Australia needs manufacturing.

Manufacturing creates employment

Next he looked at the contribution of manufacturing to employment and why we have employment issues in Australia. Yes I know the official unemployment figure is low, but that is because many people looking for work are not included in the official figure. So here is how is pans out for employment:

- For each manufacturing job, there are 2.5 other jobs created around it

- In Australia where there are 1 million jobs in manufacturing, that means there are 3.5 million jobs in total associated with manufacturing

- For each working person, there is a dependent person relying on them for income. These can be relatives, children, spouse etc.

- So in total there are 7 million people in Australia dependent on manufacturing

Now lets look at mining:

- For each mining job, there is another job created around it

- In Australia where there are 200 thousand jobs in mining, that means there are 400 thousand jobs in total associated with mining

- For each working person, there is a dependent person relying on them for income. These can be relatives, children, spouse etc.

- So in total there are 400 thousand people in Australia dependent on mining

So the current government policies and industry practices of reducing manufacturing and increasing mining for direct export are actually economic suicide.

The service industry is even worse for indirect job creation though it does employ more people than mining ever will:

- For each service industry job, there are 0.5 jobs created around it

- The ABS statistics for 2010 show roughly 3 million people working in service industries in total including the 0.5 jobs created

- For each working person, there is a dependent person relying on them for income. These can be relatives, children, spouse etc.

- So in total there are 6 million people in Australia dependent on service industry jobs

What this means is that manufacturing is actually the most critical sector in Australia in terms of job creation and future prosperity.

So lose manufacturing, and you lose a huge number of jobs.

The USA has shed 5 million manufacturing jobs since 2000, primarily to off-shoring manufacturing to lower cost economies. These jobs were replaced by low paying personnel service jobs. The net result is record levels of unemployment and a trade deficit in every manufacturing category.

He also spoke of the hidden categories, particularly in industrial products, that lead to high export incomes and have been strength of many European Manufacturers. The following diagram shows the attributes that make these products possible. Note that 4 are to do with knowledge, and 4 to do with structure and relationship. This implies you need both.

Invisible Middle Market

Economic Growth and Competitiveness

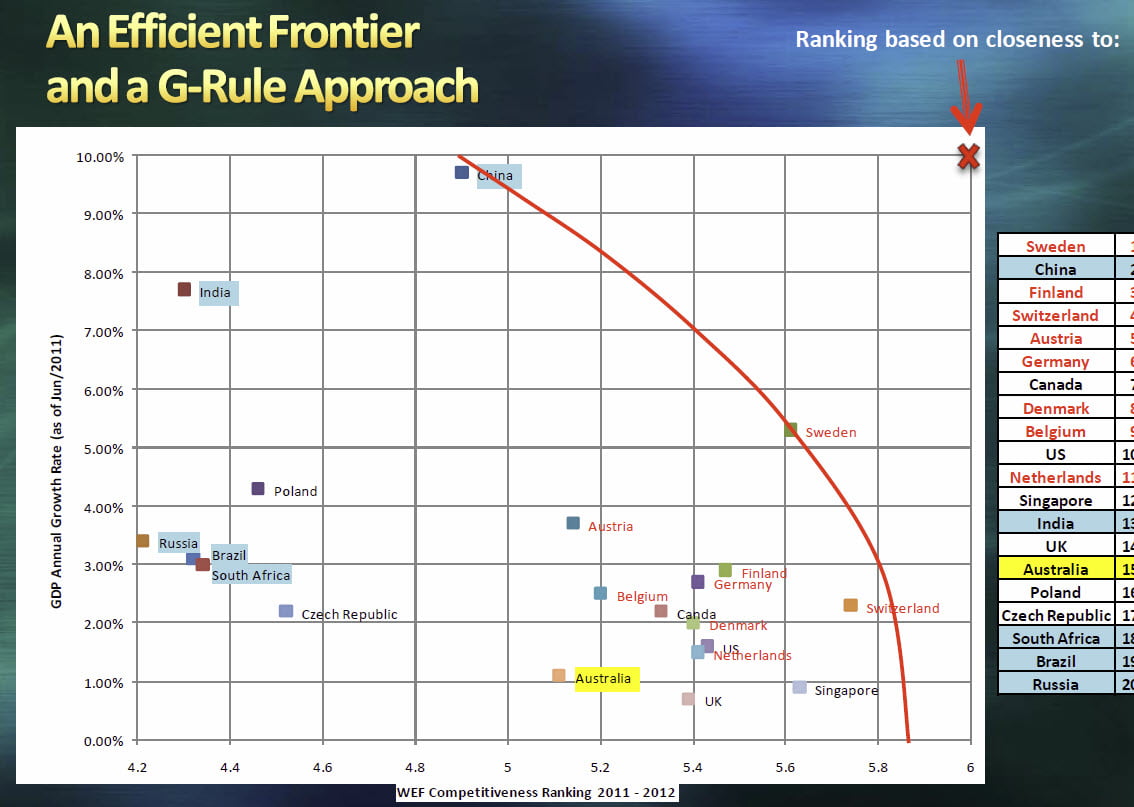

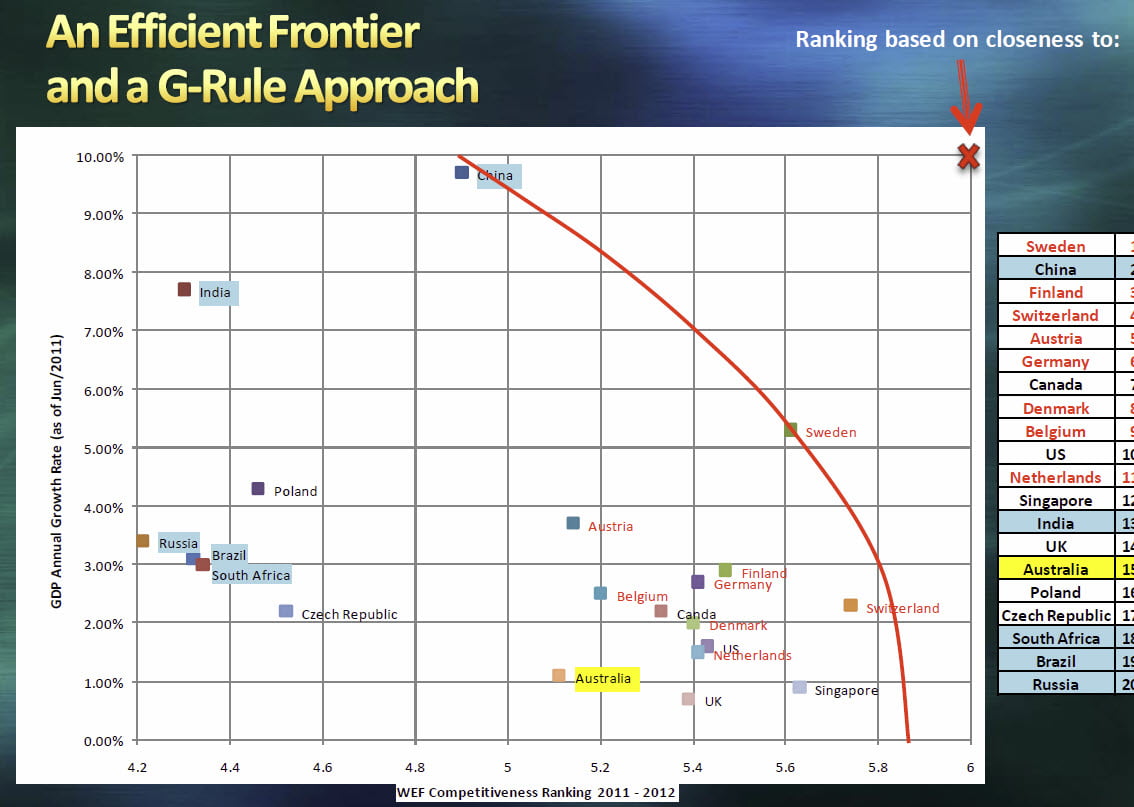

Economic growth is a measure of how well you have been doing up to now. It is a measure of the past performance. It applies to yesterday.

Competitiveness is a measure of how well you will keep doing. It is a measure of likely performance. It applies to tomorrow.

So it is more important for the future to be positioned to be competitive, than it is to have had past economic growth. Ideally you will have both.

Some examples of countries that are highly ranked for competitiveness and also economic growth are:

- China

- Singapore

- Switzerland

- Sweden

- Finland

That was a surprise. Australia ranks at number 15 for competitiveness and growth according to this analysis. The red line is the frontier of highest competitiveness. Australia is a long way from it.

Future Economic Success

Innovation

Goran Roos also had an interesting take on innovation and this fits in nicely with the view of Edward De Bono on Creating Value. He defines two types of innovation that are required to address Australia’s lack of competitiveness:

- Innovate to create value

- Innovate to retain value

Based on this, off-shoring is a really bad idea. It is only done to reduce overheads for cost based activities. For value based activities where we retain the value and the income from that value in Australia, we should be onshoring!

Knowledge

Manufacturing is the fastest knowledge growth domain. This is an interesting claim and one that had a case put for it to demonstrate the validity. Here is the case:

- Manufacturing generates 15 times the knowledge that mining does per unit of economic activity

- Manufacturing generates 3 times the knowledge that service industries do per unit of economic activity

Professor Goran Roos also pointed out that knowledge is like a race. If you slow down for a bit, then you can’t catch up if the other runners keep going full steam ahead.

Onshoring

It now makes sense that mining for export is not that great an option. Take something of huge potential value, and give it away at the lowest point you can in the value chain.

Onshoring means we pull value creating back in Australia so we get paid for it. And making stuff, and providing the service industries to support that should be our primary strategy for the future.

The other point Professor Goran Roos made is that Australia is not a scale based economy. We don’t have a large local market by world standards and so we should focus on product categories which do not require scale. Or in my language: lower volume, higher value add products. This is also know as Niche Electronics Manufacture.

All graphics are Copyright © Goran Roos 2011.

Successful Endeavours specialise in Electronics Design and Embedded Software Development. Ray Keefe has developed market leading electronics products in Australia for nearly 30 years. This post is Copyright © 2011 Successful Endeavours Pty Ltd